E-waste management has become an increasingly important consideration for the modern business place. This is because more and more e-waste is being produced that needs safe handling.

Additionally, waste management systems are looking at becoming more sustainable and environmentally friendly. This carries over into e-waste management.

Considering that it is an industry of technological innovation, it is natural that many manufacturers and producers are building electronic products with sustainability in mind.

This blog explores a number of e-waste management tips and practices that can be used in the modern business environment. Managers and business owners alike can use this to improve their e-waste management systems.

What is E-Waste?

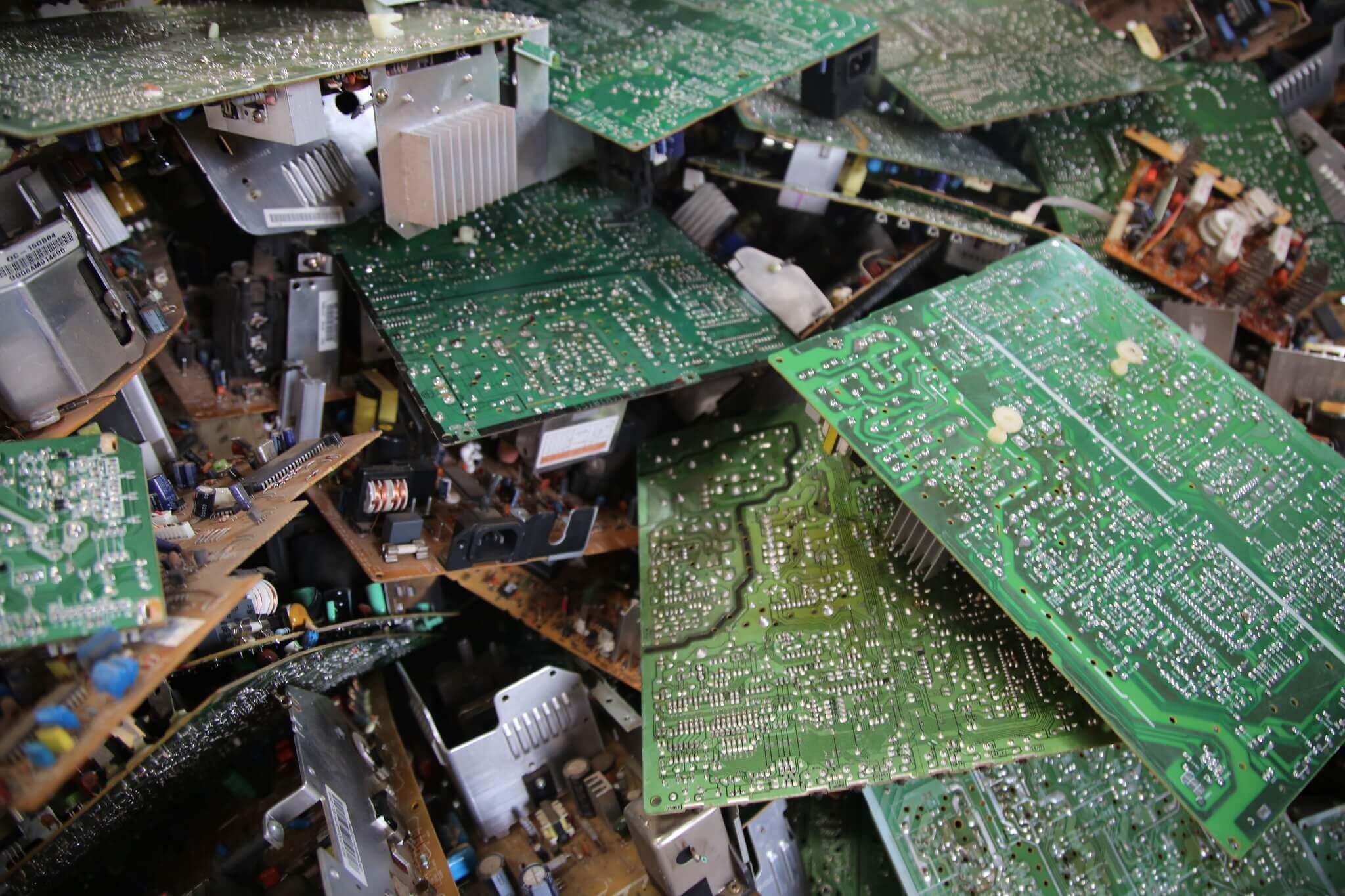

Electronic waste (e-waste) refers to the various types of waste produced when electronic products and materials are disposed of or become in excess.

Basically, e-waste is any electronic material that is now waste. It’s quite a large type of waste and can continue various different minerals. This means that electronic waste can contain potentially harmful chemicals and other hazardous materials.

It’s important that proper waste disposal techniques are practised whenever dealing with e-waste. This helps to ensure that unnecessary harm is not caused to human health or the environment.

Common Types of Electronic Waste

Common types of e-waste are found in both households and commercial business places. They’ve become ubiquitous in our daily lives.

Here’s a short list of some common types of e-waste.

- Mobile phones: Discarded due to upgrades or damage; they contain valuable metals.

- Laptops and desktop computers: Outdated or malfunctioning models with recyclable parts.

- Tablets: Broken screens or outdated technology need proper disposal.

- Printers: Non-functional or obsolete printers made of plastic or metal.

- Keyboards: are worn-out or incompatible peripherals made of plastic and electronic components.

- Hard drives: Replaced due to insufficient storage capacity or malfunction, which contained sensitive data.

- Cables and chargers: Unusable due to damage or obsolescence; frequently contain copper and plastic.

- TVs (televisions): Damaged or outdated flat screens or CRTs that contain hazardous materials.

- DVD players: non-functional or obsolete devices with recyclable components.

- Digital cameras: broken or outdated models that contain electronic components and batteries.

- Microwaves: broken units that contain electronic circuitry and metal

- Refrigerators: non-working units with electronic controls and coolant chemicals.

- Washing machines: Discarded due to mechanical failure or upgrades, including electronics.

- Batteries: Used or expired batteries that contain heavy metals and toxic chemicals.

- LED Bulbs: Burned or broken bulbs containing electronic components and glass.

It’s important to note that there are many common materials used in a variety of e-waste products, such as plastic and precious metals like copper, zinc, and gold. Dealing with these materials are part of the e-waste disposal process.

E-Waste Management Techniques

E-waste management techniques borrow from various waste management best practices and strategies. Modern waste management techniques seek to promote environmental best practices like recycling and reducing waste.

General trends in waste management have seen a desire to reduce waste in the production and manufacturing stage. Doing so reduces the total amount of waste that needs to be dealt with. It also helps to lessen the burden of obtaining new materials.

There are a number of ways to achieve this.

E-waste Recycling

E-waste recycling is a tried and tested way to manage e-waste efficiently and in an environmentally friendly manner. It’s probably the first thing someone thinks of when they consider being more eco-friendly. Cleanway even has a whole blog dedicated to its importance.

E-Waste Closed-loop Manufacturing

Closed-loop manufacturing sees manufacturers designing products that can be recycled and reformed into new products. They’re great for e-waste items that contain valuable minerals like zinc and copper. Additionally, they help to foster an electronics industry that seeks environmental best practices.

The E-Waste Circular Economy

Circular economies are similar to closed-loop manufacturing. However, while the latter focuses on the industrial stage, circular economies refer to entire economies that are self-sufficient and seek to reduce waste through reuse and recycling.

E-Waste Audits

A great way for a company to better understand their e-waste management practices is to conduct a waste audit. Waste management companies like Cleanway offer waste audit services to their customers. They will then use their audit to suggest improvements for their waste management systems.

- For more information about the various e-waste disposal techniques, be sure to visit Cleanway’s blog 25 E-waste Disposal Best Practices.

Benefits of E-waste Management

The benefits of effective e-waste management follow similar trends to other waste management techniques. This is because effective waste management follows a logical progression. The best is that it can be used as a model for promoting recycling and efficient business practices.

Environmental Benefits

The environmental benefits of e-waste management begins with more efficient resource management. Reusing materials means that fewer products need to be introduced during the production process.

For e-waste, this includes a smaller amount of raw materials needed. When it comes to fossil fuels and other finite resources, this has lost lasting effects. A lesser demand for resources means that harmful environmental practices will decrease.

The cobalt found in some cell phone batteries are a great example of this. Companies that repurpose old batteries and reuse this valuable resource decrease the need for mining and other ore extraction.

Social Benefits

The social benefits of moving towards more efficient and environmentally friendly e-waste management practices are far reaching. Many consumers want to live in a greener future, so following waste best practices can help to build a future that many people desire.

Companies that adopt e-waste management best practices that reduce climate change and greenhouse gas emissions from carbon dioxide will also help to foster an entire green economy. It really is an example of everyone doing their part in building a future together.

Many employees and customers can also feel empowered when companies adopt effective e-waste management techniques. They will feel like they are part of this future and will likely favour your company for it.

Economic Benefits

The many economic benefits follow suit from these environmental and social benefits. This is because a green economy is also an efficient economy. This will help to save costs and reduce unnecessary production.

An industry that pushes itself towards efficiency and environmentally friendly practices will find itself at the forefront of innovation. More customers will follow suit, as well as greater competition all-round.

E-waste also has the added advantage of being potentially profitable. Reselling e-waste, either in part with the various minerals extracted, is a great secondary source of income for any company.

Future of E-Waste Management

The future of e-waste management, like the waste management industry, will likely see a continued push towards finding more environmentally friendly solutions to waste disposal.

Electronic companies have the added advantage of working in an industry that is itself innovative. The continued production of their goods and services should see more and more effective waste management.

Electrical and electronic equipment has become prevalent in our daily lives. It’s unlikely that electronic devices like mobile phones will stop being important in some form or another.

It’s safe to say that electrical and electronic waste will continue to exist in the future. What’s important is for a continued push for e waste recycling and environmentally sound management production processes.